Powder Metallurgy Structural Parts

Precision-engineered structural components manufactured with advanced powder metallurgy technology. Trusted by manufacturers worldwide for over 20 years.

H&Z is a trusted global manufacturer of high-quality powder metallurgy structural parts, offering comprehensive services from design and material selection to production and delivery.

We specialize in producing precision powder metal components for automotive, industrial, and home appliance applications, including engine parts, transmission systems, brake components, and hydraulic systems. Our advanced powder metallurgy technology ensures tight tolerances, cost efficiency, and consistent reproducibility, making us a reliable partner for both low and high-volume production needs.

With state-of-the-art facilities and rigorous quality control processes, we deliver durable and high-performance custom powder metal parts tailored to your specific requirements. Whether you need VVT components, timing system parts, or industrial machinery components, our engineering expertise and competitive pricing ensure cost-effective solutions without compromising on quality.

Powder metallurgy is an advanced manufacturing process that produces complex, high-performance parts with tight tolerances and consistent quality. By using metal powders, components achieve exceptional strength and durability, making them ideal for demanding applications. This technology also reduces material waste and eliminates the need for secondary operations, significantly reducing production costs.

Benefits of Powder Metallurgy for Structural Parts

Powder metallurgy offers significant advantages for structural component manufacturing, making it the preferred choice for many applications.

Cost-Effective Manufacturing

Lower tool costs and reduced material waste compared to traditional machining. Ideal for high-volume production from 5,000 to 5 million+ units annually.

High Precision

Tighter tolerances compared to castings and stampings. Consistent reproducibility ensures uniform quality across production runs.

Design Flexibility

Elimination of draft angles and shearing requirements. Capability to manufacture increasingly complex parts with minimal secondary operations.

Superior Material Properties

Parts with higher density and strength. Ability to create unique material compositions and incorporate special features.

Material Efficiency

Minimal waste material as powder metallurgy is a near-net-shape process. "Lightening holes" formed during compaction reduce both weight and cost.

Part Consolidation

Ability to combine two or more discrete parts into a single component, reducing assembly costs and improving reliability.

Our Powder Metallurgy Structural Parts

We manufacture a wide range of precision structural components using powder metallurgy technology.

Automotive Structural Parts

Timing Structural Parts

VVT Structural Parts

Home Appliances Structural Parts

Production Equipment

State-of-the-art manufacturing equipment ensuring high precision and efficient production.

Production Equipment

Advanced machinery for precision manufacturing

Industry Applications

Powder metallurgy structural parts are widely used across various industries due to their precision, durability, and cost-effectiveness.

Automotive

- Engine components

- Transmission systems

- Brake parts

- VVT systems

Industrial

- Machinery components

- Hydraulic systems

- Pumps and valves

- Industrial equipment

Home Appliances

- Washing machines

- Refrigerators

- Power tools

- Household accessories

Timing Systems

- Timing components

- Drive systems

- Pulleys and gears

- Sprockets

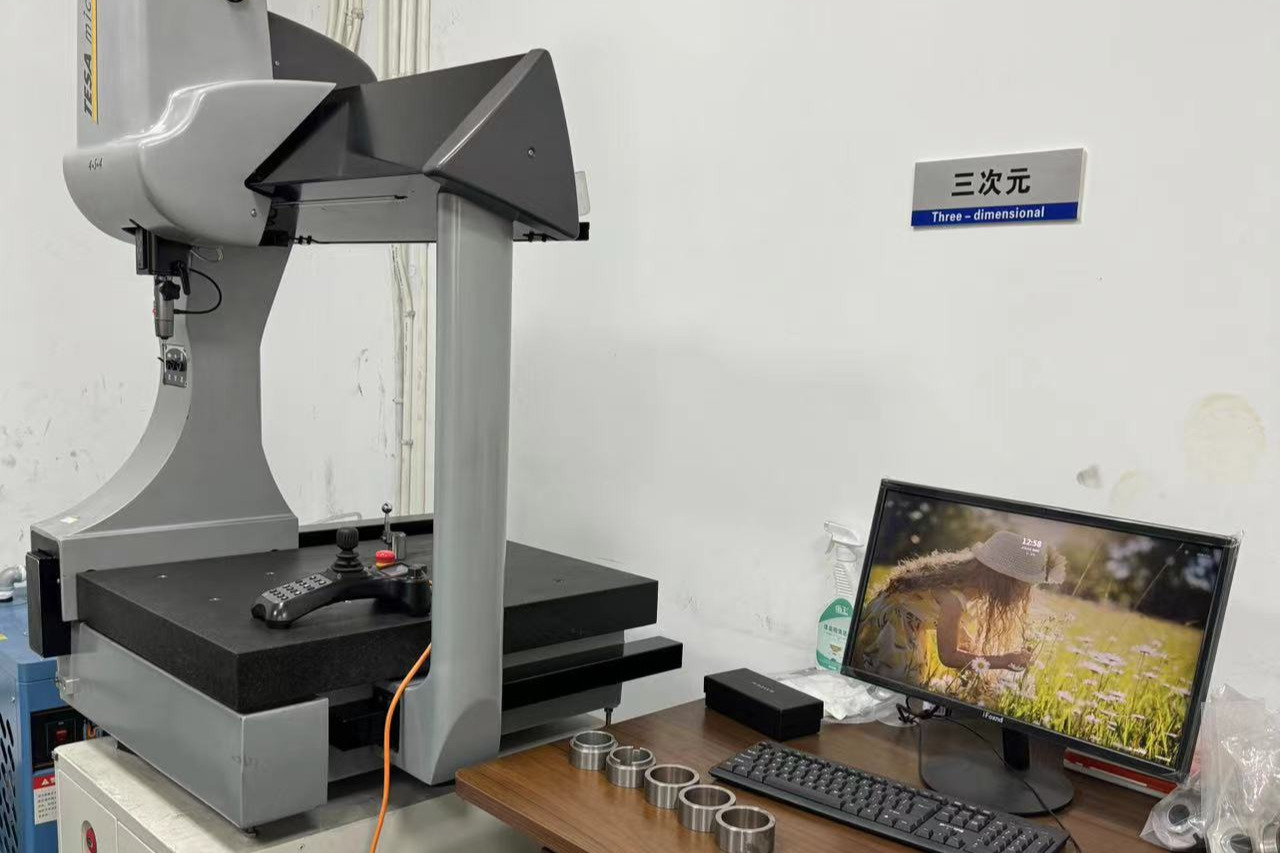

Test Equipments

Precision testing equipment ensuring every part meets strict quality standards.

Test Equipments

Advanced testing for quality assurance

Available Materials

We offer a comprehensive range of materials for powder metallurgy structural parts, each selected for specific performance characteristics.

Stainless Steel

Available in 300 and 400 series. Excellent corrosion and rust resistance, ideal for demanding environments.

Iron & Steel

The most common PM material. Iron powder produces cost-effective parts for structural components.

Copper & Bronze

Copper alloys offer corrosion resistance and self-lubricating properties. Bronze for bearing applications.

Nickel & Molybdenum

Superior strength and heat resistance for high-stress structural applications.

Aluminum

Lightweight with excellent formability. Ideal for weight-sensitive applications.

Composite Materials

Custom material combinations tailored to specific performance requirements.

Our Manufacturing Services

H&Z provides comprehensive powder metallurgy services from material development to finished product delivery.

| Service | Details |

|---|---|

| Material Selection & Development | Provide a variety of metal powder material options, support customized development, and meet specific performance requirements. |

| Mold Design & Manufacturing | Professional team and advanced technology ensure the realization of high precision and complex geometric shapes. |

| Powder Pressing | High-precision equipment supporting unidirectional pressing, bidirectional pressing, and isostatic pressing. |

| Sintering Process | Equipped with advanced sintering furnaces with atmosphere control (hydrogen, nitrogen, etc.). |

| Post-Processing & Surface Treatment | Including finishing, heat treatment, and surface treatment (such as electroplating, coating, etc.). |

| Quality Control & Testing | Use advanced equipment such as three-coordinate measuring machines for strict quality control. |

| Customized Production | From small batch trial production to large-scale mass production, flexibly meeting customer needs. |

| Industry Application Support | Provide customized solutions for multiple industries, ensuring product performance meets standards. |

| Environmental Sustainability | Using near-net-shape technology to reduce material waste and energy consumption. |

Factory Production Process

Experience our state-of-the-art manufacturing facility and see how we produce high-quality structural parts.

Frequently Asked Questions

Q: What are the best materials for powder metallurgy structural parts?

Iron-based powders are the most commonly used materials for structural parts due to their excellent mechanical properties and cost-effectiveness. However, we also offer stainless steel, copper alloys, nickel, molybdenum, and aluminum depending on your specific requirements. Our engineering team can help you select the optimal material based on strength needs, corrosion resistance, temperature requirements, and cost constraints.

Q: What tolerances can powder metallurgy achieve for structural parts?

Powder metallurgy can achieve very tight tolerances, typically within ±0.1% of the nominal dimension. This is often better than casting or stamping processes. Our advanced manufacturing capabilities ensure consistent reproducibility across production runs, making PM ideal for high-precision structural applications.

Q: Can you handle both small batch and high-volume production?

Yes, we specialize in accommodating both low and high-volume production needs, from 5,000 to over 5 million units annually. Our flexible manufacturing approach ensures cost-effective solutions whether you need prototype quantities or full-scale production runs.

Why Choose H&Z for Your Structural Parts

IATF-16949 Certified

Quality management system certified specifically for automotive manufacturers.

Full-Service Manufacturing

From design to delivery, including machining, plating, and heat treatment.

Advanced Engineering

Dedicated engineering team with extensive powder metallurgy expertise.

Competitive Pricing

Professional manufacturing in China with cost-effective solutions.

Ready to Customize Your Structural Parts?

Contact our engineering team to discuss how powder metallurgy can improve your structural components.

Request a Quote